Got a roof project and need to understand commercial roofing terms? This atlantacommercialroofingcontractors.com guide simplifies key terms to give you the proper knowledge to help you make smart decisions and communicate clearly with contractors.

Key Takeaways

- Understanding roof types (steep-slope vs. low-slope) is essential for selecting appropriate materials and drainage solutions in commercial roofing.

- Key roofing components, such as the roof deck, underlayment, and flashing, are essential for ensuring the strength, stability, and waterproofing of a commercial roofing system.

- Regular maintenance and awareness of common roofing issues, such as blistering and ponding, are crucial for extending the lifespan of commercial roofs.

Roof Slope and Types

The roof slope, or the angle at which a roof slants, is a key aspect of any roofing system. It affects how well water is drained off the roof, helping to prevent water damage. The slope is usually measured by the vertical rise per 12 inches of horizontal run.

Commercial roofs generally fall into two categories: steep slope and low slope. Each type has its unique applications and benefits, influencing the roofing materials and systems used.

Steep-Slope

Steep-slope roofs, with a pitch steeper than 3:12, are less common in commercial architecture but are sometimes chosen for aesthetic or functional reasons. These roofs are more typical in residential settings because they shed water quickly, minimizing the risk of leaks and water damage.

However, they demand carefully selecting roofing systems and materials to guarantee longevity and performance.

Low-Slope

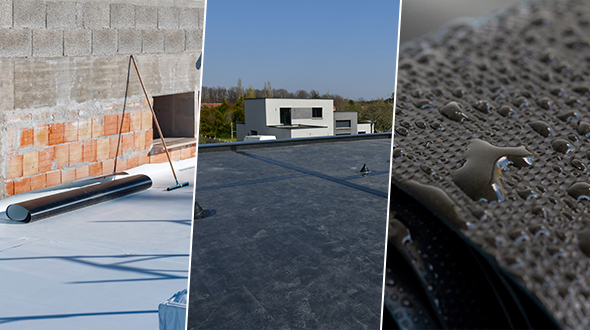

Low-slope roofs, often called flat roofs, are standard in commercial and industrial buildings. These roofs have a minimal slope, typically 1/4 inch per foot or less, necessitating effective drainage solutions to avoid water pooling.

Low-slope roofs are easier to construct and maintain over large areas, making them a cost-effective choice for commercial applications.

Roofing Materials

Selecting the appropriate roofing material is crucial for the durability and efficiency of a commercial roof. Different materials provide varying levels of protection, energy efficiency, and longevity. Common roofing materials include metal roofs, built-up roofing systems, and single-ply membranes.

Each material has unique properties and benefits, making it suitable for specific environmental conditions and architectural requirements.

Built-Up Roofing (BUR)

Built-up roofing (BUR) is a traditional system composed of multiple layers of bitumen sheets. This layered approach offers enhanced protection and durability, making it popular for commercial and industrial buildings.

The cap sheet, also known as the top layer, adds an extra defense against weather elements, ensuring the roofing system’s longevity.

Single-Ply Roofing Membranes

Single-ply roofing membranes, such as TPO, PVC, and EPDM, are favored for their flexibility and ease of installation. These membranes offer excellent weather resistance and energy efficiency.

EPDM, for instance, is valued for its low cost and high energy efficiency, making it a popular choice for commercial roofs.

Modified Bitumen Roofing

Modified bituminous roofing blends traditional asphalt with modern polymers, producing materials like SBS and APP, including polymer-modified bitumen and roofing asphalt conforming. These materials provide enhanced flexibility and temperature resistance and are suitable for various climates and building types.

The composition of modified bitumen offers a robust and durable roofing solution for commercial applications.

Key Roofing Components

A commercial roofing system comprises various components, each playing a crucial role in its performance. Key components include the roof deck, underlayment, and roof covering, working together to offer structural support, moisture protection, and weather resistance.

Grasping the function of these components ensures the roofing system’s longevity and efficiency.

Roof Deck

The roof deck serves as the base supporting all other roofing materials. It is typically made from wood, steel, or concrete, depending on the building’s structural deck needs. The material choice for the roof deck can significantly affect the roofing system’s overall durability and performance.

Underlayment

Underlayment acts as an extra protective layer between the roof deck and the roof covering. Its main function is to provide secondary moisture protection, preventing leaks and extending the roof’s lifespan.

The underlayment is critical for the roof’s overall waterproofing.

Roof Covering

The roof covering is the outermost layer of the roofing system, directly exposed to the elements. It can be made from materials like metal panels, EPDM, or TPO membranes. The choice of roof covering depends on factors such as weather conditions, building design, and budget.

Each type provides varying levels of protection and durability.

Waterproofing and Insulation

Effective waterproofing and insulation are key to maintaining a commercial roof’s integrity and efficiency. These elements prevent water infiltration and heat loss, which can cause structural damage and raise energy costs.

Properly installed waterproofing materials and insulation significantly boost the roof’s performance and longevity.

Vapor Retarder

A vapor retarder is key in controlling moisture within a roofing system. It acts as a barrier to slow water vapor movement, preventing condensation and potential damage to insulation and other materials.

Vapor retarders help maintain the roof’s thermal efficiency and structural integrity.

Roof Coating

Roof coatings are applied to enhance weather resistance and durability. They form a protective layer that shields underlying materials from UV rays, rain, and other elements.

These coatings provide a cost-effective solution for maintaining commercial roofs, helping to extend their lifespan and reduce the need for frequent repairs or replacements.

Insulation

Insulation is crucial for improving energy efficiency in commercial buildings. It helps maintain a stable indoor temperature by preventing heat loss in winter and heat gain in summer. Proper insulation enhances comfort and reduces energy costs, making it essential for any roofing system.

Protective Features and Accessories

Protective features and accessories are essential for extending the life and performance of commercial roofing systems. Components like flashing, drip edges, and ballast provide extra protection against environmental elements and enhance the roof’s overall efficiency.

These features are vital for a robust and durable roofing system.

Flashing

Flashing is a thin, weatherproof material used to seal joints and prevent water infiltration in critical roof areas. It protects where the roof meets walls, chimneys, or other vertical surfaces.

Proper flashing installation is crucial for the roof’s waterproofing.

Drip Edge

A drip edge is a metal strip positioned along the roof’s edge to guide water away from the roofing materials and into the gutters. This prevents water from seeping into the roof deck and causing damage.

Drip edges are a simple yet effective component for protecting the roof’s structural integrity.

Ballast

Ballast, such as precast concrete or aggregate, holds roofing materials in place through gravity. This method secures membranes and protects against wind uplift.

The ballast provides stability and enhances durability.

Installation Techniques

Proper installation techniques are essential for ensuring roofing systems’ effectiveness and longevity. Methods like mechanical fastening, adhesive application, and heat welding secure roofing materials and components.

Knowing these techniques helps select the best approach for different roofing projects.

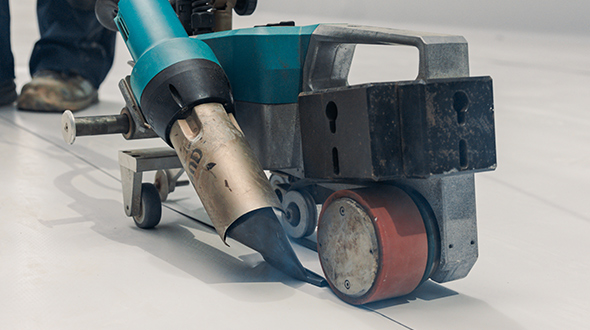

Heat-Fused

The heat-fused method involves heating the underside of roofing materials to ensure strong adhesion. This technique creates a durable bond, enhancing the roofing system’s integrity.

Heat-fused installations are particularly effective for creating a strong waterproof barrier.

Back-Nailing

Back-nailing is a technique where fasteners are concealed by the ply, resulting in a cleaner roof surface. This method improves weather resistance and reduces the risk of leaks by hiding the fasteners from environmental exposure.

Back-nailing also enhances the roofing system’s overall durability.

Phased Application

The phased application allows roofing projects to be completed in stages, accommodating scheduling and budget constraints. This method offers flexibility, enabling work to continue despite weather changes or other delays.

The phased application suits large-scale commercial roofing projects.

Maintenance and Repair Terms

Regular maintenance and timely repairs are crucial for extending commercial roofs’ lifespan. Understanding common issues like blistering, ponding, and tear-off helps identify and address problems early.

Proper maintenance keeps the roof functional and efficient.

Blistering

Blistering occurs when moisture gets trapped within the roofing layers, causing raised bubbles on the roof surface. This issue indicates potential moisture infiltration and needs prompt attention to prevent further damage.

Proper installation and maintenance practices can help prevent blistering.

Ponding

Ponding refers to the accumulation of standing water on low-slope roofs. Prolonged ponding can indicate drainage issues and cause structural damage if not resolved.

Regular inspections and maintenance are crucial to prevent ponding and its associated problems.

Tear-Off

Tear-off involves removing old roofing materials to prepare the roof for new installation. This process ensures the new roofing system is installed on a clean, solid foundation, enhancing performance and longevity.

Tear-off is a crucial step in comprehensive roof replacement projects.

Performance Metrics

Performance metrics are key for evaluating the efficiency and durability of roofing materials and systems. Metrics like R-value, reflectance, and compressive strength provide insights into the roof’s performance under various conditions.

Knowing these metrics helps make informed decisions about roofing materials and installations.

R-Value

R-value measures the thermal resistance of roofing materials, indicating their effectiveness in insulating the building. A higher R-value signifies better insulation properties, leading to improved energy efficiency and reduced heating and cooling costs.

Reflectance

Reflectance refers to the ability of roofing materials to reflect sunlight, helping to keep the cold roof surface cool. High-reflectance materials can reduce the heat absorbed by the roof, enhancing energy efficiency and prolonging the roof’s lifespan.

Compressive Strength

Compressive strength measures a material’s ability to withstand axial loads without failure. High compressive strength is crucial for roofing materials as it ensures durability under heavy loads and extreme weather conditions. Factors like material composition and density influence compressive strength.

Roof Terms Summary

Understanding commercial roofing terms is fundamental for making informed decisions about your roofing needs. From roof slopes and materials to installation techniques and maintenance, each aspect plays a crucial role in the performance and longevity of a roof. By familiarizing yourself with these terms, you can ensure your commercial roof is well-constructed, durable, and efficient. Remember, a well-maintained roof is key to protecting your investment and ensuring the safety and comfort of those inside.

Frequently Asked Questions

What is the purpose of a roof slope?

The roof slope is crucial for effective water runoff and drainage, helping to prevent water damage to the roof structure. A well-designed slope minimizes the risk of leaks and extends the roof’s lifespan.

What are the main types of single-ply roofing membranes?

The main types of single-ply roofing membranes are TPO (Thermoplastic Polyolefin), PVC (Polyvinyl Chloride), and EPDM (Ethylene Propylene Diene Monomer). Each offers unique benefits suited to different roofing needs.

Why is underlayment important in roofing systems?

Underlayment is crucial in roofing systems as it offers secondary moisture protection, significantly enhancing waterproofing and helping to prevent leaks. Its inclusion is essential for maintaining the roof’s integrity and longevity.

What is blistering in roofing terms?

Blistering, in roofing terms, is the formation of raised bubbles on the roof surface, signifying possible moisture infiltration in the roofing layers. This issue can lead to significant damage if not addressed promptly.

How does the R-value affect roofing performance?

R-value significantly impacts roofing performance by indicating the material’s insulation effectiveness; a higher R-value ensures better energy efficiency and thermal resistance, leading to more comfortable indoor climates.

(404) 220-9288