When addressing roofing for low-slope structures, selecting the right materials and installation techniques is not just a choice—it’s a necessity. This article provides the essential knowledge you need on effective low-slope roofing, ensuring your building stays protected and performs well over time. Expect a focused look at the best practices for choosing and maintaining a low-slope roof.

Key Takeaways

- Low slope roofs, with a pitch below 2:12, require specific materials like TPO, PVC, EPDM, modified bitumen, or metal roofing systems for durability and to prevent water damage.

- Proper installation techniques, such as fully adhered systems, mechanically fastened solutions, and heat-welded seams, are critical to the longevity and functionality of low-slope roofs.

- When selecting a low-slope roofing system, important considerations include climate compatibility, roof traffic, durability, cost versus life expectancy, and innovations like modular systems and cool roofing technologies.

Understanding Low-Slope Roofing

When it comes to low-slope roofs, understanding the basics is akin to laying a strong foundation for your house. Imagine a roof with a gentle incline—that is the essence of a low-slope roof, characterized by a pitch below 2:12. This architectural choice has significant implications for material selection and installation, as it demands a keen eye and experience to prevent water damage and ensure longevity.

The Basics of Roof Slope

Diving deeper into the concept, roof pitch is the measurement that dictates how steep a roof is. Like a silent guardian, it influences everything from aesthetic appeal to the practicality of water runoff. Defined by its rise over a 12-inch span, roof pitch/slope is a critical factor in choosing the right roofing materials.

Roof pitch ratio (ex. 2:12) is a way to measure the steepness of a roof. Here’s how it works:

- The first number (2 in this case) tells you how many inches the roof rises (goes up) for every 12 inches it runs (goes across).

- The second number (12) is always the same and represents the horizontal distance of one linear foot.

So, a 2:12 pitch means that for every 12 inches you go horizontally (across), the roof goes up 2 inches.

Why Roof Pitch Matters

Here’s where it gets real: the pitch of your roof isn’t just about looks; it’s about protecting your property from the elements. A low-slope roof requires materials that can endure prolonged exposure to water, fend off UV rays, and withstand debris accumulation. It’s a delicate balance of functionality and design that ensures a roofing system can weather the storm.

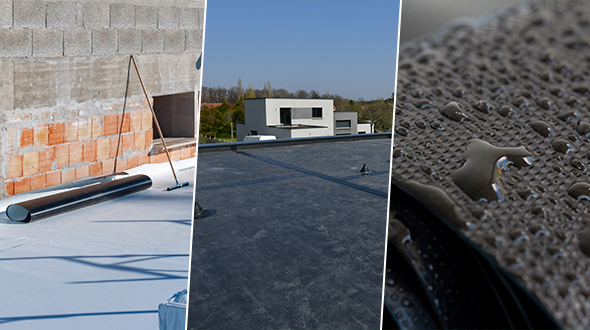

Essential Materials for Low-Slope Roofs

When selecting materials for low-slope roofs, it’s not just about picking the toughest material but choosing the right ally for the battle against the elements. Membrane roofing, modified bitumen, and metal roofing systems lead the charge with their durability and weather resistance, making them the stalwarts of low-slope roofing.

Membrane Marvels: TPO, PVC, and EPDM

In the world of membrane roofing, TPO, PVC roofs, and EPDM stand tall as the trinity of protection, offering longevity and resilience to rooftop traffic. With lifespans stretching up to 40 years and heat-reflective surfaces to boot, these membranes are not just covers but shields against the harshest of climates.

Modified Bitumen: The Modern Twist on Asphalt

Modified bitumen systems offer the following benefits for modified bitumen roofs:

- Flexibility and waterproofing prowess needed for low-slope roofs

- Modern-day armor for buildings, combining traditional familiarity with innovative resilience

- Available in variations like APP (plastic asphalt) and SBS (elastic asphalt) for tailored performance

Metal Roofing Mastery

For those seeking the zenith of longevity and aesthetics, standing seam metal roofing is the crown jewel. Flaunting up to 50 years of life, this premium choice for low-slope roofs marries function and form with concealed fasteners and a palette of colors to accentuate any building’s silhouette with a standing seam metal roof.

Installation Techniques for Peak Performance

Even the finest roofing materials are only as good as their installation. Techniques such as fully adhered systems, mechanically fastened solutions, and heat-welded seams are the key to ensuring your low-slope roof stands tall against time and nature.

Fully Adhered Systems (Adhesive)

These are single-ply roofs secured using exceptionally strong adhesive. Roofers apply the adhesive uniformly across the entire membrane, anchoring it firmly to the underlying layer. This comprehensive adhesion is the reason these roofs are termed “fully” adhered.

Fully adhered systems offer the following benefits:

- Seamless look

- Added noise dampening

- Minimal maintenance

- Fortification against wind uplift and water infiltration

With fewer seams and opportunities for leaks, this method not only beautifies the structure but also enhances its functionality.

Mechanically Fastened Solutions (Fasteners)

Mechanically fastened roofs are secured using specialized fasteners. For single-ply mechanically fastened roofs, these fasteners are generally screws, but their material, length, and other specifics are determined by the roof’s substrate. Different substrates like steel, concrete, wood, and lightweight gypsum decks each necessitate unique fastener types. Roofers also use plates with the fasteners to distribute the force applied to the membrane, ensuring a more secure and durable attachment.

In the face of high winds, uplift forces and demanding weather conditions, mechanically fastened solutions stand firm, anchoring the roof with reliability. Precision in sealing penetrations is the name of the game here, ensuring that leaks are kept at bay for a steadfast roofing system.

Heat-Welded Seams for Superior Seal

Heat-welded seams are the artisans of roofing, meticulously crafting an impenetrable barrier that locks out moisture and safeguards the roof’s integrity. With specialized equipment, roofers create bonds that are not only robust but also crucial in preventing the roof’s degradation over time.

Critical Considerations for Low-Slope Roofing

Certain elements are non-negotiable in the grand scheme of roofing. Climate, foot traffic, and the delicate dance of cost versus life expectancy are considerations that can make or break the success of a low-slope roofing system.

Climate Compatibility

The climate’s whims can test the mettle of roofing materials, which is why it is imperative to choose ones that can withstand the local weather patterns. From the sun-absorbing prowess of EPDM to the uplift resistance of fully adhered systems, climate compatibility is a cornerstone of roofing choice.

Foot Traffic and Durability

Commercial and industrial low-slope roofs, also known as flat roofs, are battlegrounds for durability. Materials must endure foot traffic and environmental stresses alike. It’s about choosing a roofing system that maintains structural integrity despite constant commercial activity.

Cost vs. Life Expectancy

The alchemy of cost-effectiveness in roofing involves balancing upfront investments with long-term benefits. Life expectancy and warranties play a pivotal role in determining whether a roofing system is a wise economic move or a penny-wise but pound-foolish decision.

Innovations in Low-Slope Roofing Systems

As the roofing industry marches forward, innovations such as prefabricated modular systems, cutting-edge materials, and the bur roofing system redefine what’s possible. These advancements not only streamline installation but also push the boundaries of energy efficiency and structural integrity.

Green Roofing Systems

Green roofing systems are a testament to the harmonious blend of nature and architecture. Offering a plethora of benefits like:

- insulation

- urban heat reduction

- stormwater management

- improved air quality

- increased biodiversity

These living roofs are not only visually stunning but also environmentally sound, albeit with the caveat of higher maintenance needs.

Cool Roofing Technologies

Cool roofing technologies are the unsung heroes in the fight against urban heat, employing reflective coatings and pigments that turn roofs into shields against the sun’s heat. With materials like PVC and TPO leading the charge, cool roofs are a smart choice for those looking to improve energy efficiency while mitigating their ecological footprint.

Preventing Common Low-Slope Roof Issues

A low-slope roof, also known as a flat roof, has one major enemy: stagnation—of water. Preventing common issues such as leaks and water accumulation is paramount for the roof’s health and the safety of those beneath it.

Ensuring Proper Drainage

A roof’s drainage system is its lifeline, ensuring that water is swiftly escorted away, thus averting the risks of structural overload. Regular maintenance and strategic design choices like additional drainage lines and tapered insulation crickets are essential for a dry and durable roof.

Mitigating Leak Risks

To keep leaks at bay, entrusting the installation to skilled roofers is a must. From flood testing to selecting fully adhered TPO roofing for its watertight seam, every step taken is a step towards securing a leak-free future for low-slope roofs.

The Selection Process: Finding Your Ideal Low-Slope Roof

Embarking on the quest for the perfect low-slope roof is not a solo journey. It’s about partnering with the right commercial roofer, considering the building’s aesthetics, and understanding the intricacies of the roofing materials market. It’s a strategic process that balances personal preferences with practicality and expertise.

Assessing Your Roof’s Requirements

The first step in selecting a roofing material is understanding your roof’s unique needs. By measuring its pitch and considering the building’s design, you can narrow down the materials that will provide the durability and flexibility required for your specific situation.

Consulting with Roofing Professionals

Roofing professionals are the sage advisors in the world of roofing, offering thorough evaluations and tailored solutions. Their specialized inspections can reveal issues before they escalate, ensuring that your low-slope roofing project is not only successful but also enduring.

Low Slope Roofing Summary

As we reach the pinnacle of our roofing expedition, it becomes clear that the path to a resilient and efficient low-slope roof is paved with knowledge and precision. From understanding the basics of roof pitch to embracing innovative technologies, every step is crucial in crafting a roofing system that stands the test of time. Let this guide be your compass, leading you to a roofing solution that not only protects but also elevates your property.

Roofing for Low Slope Frequently Asked Questions

What are the best materials for a low-slope roof?

For their durability and weather resistance, membrane roofing options like TPO, PVC, and EPDM, as well as modified bitumen and metal roofing systems, are the best materials for a low-slope roof. Choose one of these materials based on your specific needs.

How does roof pitch affect roofing material selection?

Roof pitch significantly impacts the ability of roofing materials to shed water and resist water penetration, especially for low-slope roofs. The pitch determines the efficiency of water shedding and overall water resistance.

Are there any innovative roofing systems for low-slope roofs?

Indeed, there are various innovative options for low-slope roofing, such as green roofing systems, cool roofing technologies, and prefabricated modular systems, which are constantly evolving to provide more choices.

How can I prevent leaks in my low-slope roof?

To prevent leaks in your low slope roof, it’s essential to hire skilled roofers for proper installation, conduct thorough inspections, and choose materials with superior sealing properties, like fully adhered TPO roofing. This will help maintain the integrity of your roof and minimize the risk of leaks.

How do I start the process of selecting the right low-slope roofing material?

Start by consulting with roofing professionals to assess your roof’s specifications and requirements. Their expert advice will help guide you in selecting the ideal material for your low-slope roof.

(404) 220-9288