When you walk into a sprawling warehouse, shop at a retail center, or work in a modern office building, you’re protected by sophisticated roofing systems that operate on an entirely different scale than residential homes. Commercial roofing represents a specialized field that encompasses far more than simple weather protection—it’s about safeguarding business operations, managing energy costs, and maintaining critical infrastructure that keeps commerce running smoothly.

Understanding what commercial roofing entails is essential if you’re responsible for a commercial property. From the materials used to the installation process, maintenance requirements, and long-term costs, commercial roofing systems differ dramatically from residential roofs in ways that directly impact your bottom line and operational continuity.

Definition of Commercial Roofing

Commercial roofing covers the installation, repair, and maintenance of roofing systems on commercial buildings, warehouses, factories, retail stores, and office complexes. These sophisticated systems protect commercial properties typically exceeding 10,000 square feet and must handle significantly heavier loads than residential roofs ever encounter.

Unlike residential roofs, which primarily focus on aesthetic appeal and basic weather protection, commercial roofs must support substantial HVAC equipment, industrial machinery, and frequent foot traffic from maintenance personnel. A typical commercial building might have multiple rooftop units weighing thousands of pounds, solar panel installations, cooling towers, and regular access for maintenance teams—demands that residential roofs aren’t designed to handle.

The primary purpose extends beyond protecting the structure itself. These roofing systems safeguard business operations, inventory valued at potentially millions of dollars, employees, and customers from weather elements such as rain, snow, hail, and wind. When a commercial roof fails, the consequences ripple through every aspect of business operations, making reliability and durability paramount concerns.

Commercial properties encompass a vast range of building types, from small retail buildings covering 5,000 square feet to massive distribution centers spanning over 500,000 square feet. Each requires a carefully engineered roofing system designed to meet specific performance criteria, building codes, and operational requirements that vary significantly based on the building’s intended use.

How Commercial Roofing Differs from Residential Roofing

The differences between commercial and residential roofing systems extend far beyond simple size considerations, encompassing fundamental design philosophies, structural requirements, and performance expectations that reflect the distinct needs of business versus residential environments.

Design and Structure

Commercial roofs are typically flat or low-slope, with pitches less than 3:12, compared to residential roofs, which feature steep pitches ranging from 4:12 to 12:12. This fundamental difference stems from functional requirements—commercial buildings prioritize maximizing interior space utilization and accommodating rooftop equipment, while residential buildings emphasize aesthetic appeal and efficient water runoff.

Commercial structures span much larger areas, often covering 50,000 to 500,000 square feet, compared to residential roofs, which average 1,500 to 3,000 square feet. This massive scale creates unique engineering challenges, particularly regarding thermal expansion and contraction across vast roof surfaces, structural load distribution, and effective water management systems.

Flat commercial roofs require sophisticated drainage systems, including internal drains, scuppers, and specialized gutters, to prevent water pooling—a critical concern, as standing water can compromise membrane integrity and create structural problems. These drainage systems must handle substantial water volumes during intense storms while preventing backup that could flood interior spaces.

Commercial roofs must support rooftop equipment weighing thousands of pounds, including chillers, cooling towers, exhaust fans, and increasingly common solar panel arrays. This equipment placement requires careful structural analysis and reinforcement, along with accessible maintenance pathways that don’t compromise the roofing system’s waterproof integrity.

Materials Used

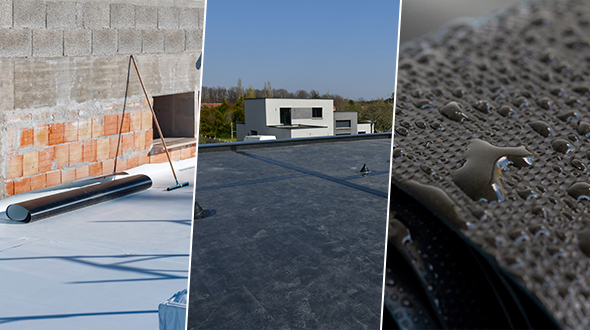

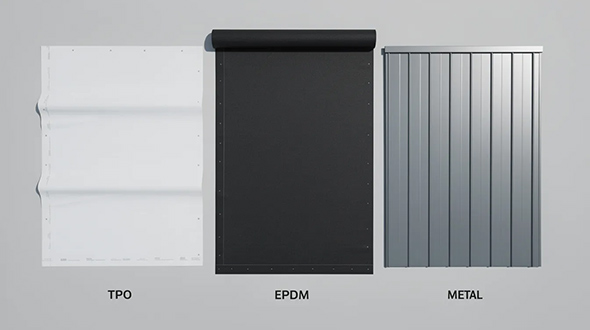

Commercial roofs utilize fundamentally different materials designed for durability, performance, and large-scale application rather than aesthetic appeal. Single-ply membranes like TPO (Thermoplastic Polyolefin), PVC (Polyvinyl Chloride), and EPDM (Ethylene Propylene Diene Monomer) dominate commercial applications due to their ability to cover large areas seamlessly and provide long-term weather resistance.

Modified bitumen systems and built-up roofing (BUR) with multiple asphalt and reinforcement layers remain common for commercial applications where extreme durability and puncture resistance are priorities. These multi-layer systems provide redundancy that single-ply systems cannot match, making them ideal for high-traffic commercial environments.

Metal roofing systems, including standing seam steel and aluminum panels, are designed for large spans and can support substantial loads while providing decades of service life. These systems often incorporate specialized coatings and insulation configurations optimized for energy efficiency in large buildings.

In contrast, residential roofs primarily use asphalt shingles, clay tiles, slate, or cedar shakes chosen for aesthetic appeal and weather protection rather than load-bearing capacity or large-scale performance. While some overlap exists in materials like metal roofing, the specifications, installation methods, and performance requirements differ substantially between residential and commercial applications.

Types of Commercial Roofing Systems

Commercial roofing encompasses several distinct system types, each engineered to address specific performance requirements, building characteristics, and operational needs. Understanding these systems helps property owners make informed decisions about new installations, replacements, and maintenance strategies.

Single-Ply Membrane Roofing

Single-ply membranes are the most widely used commercial roofing materials for flat roofs, offering efficient installation, proven performance, and energy-efficiency benefits that align with modern building requirements and environmental regulations.

TPO roofing has gained significant market share due to its energy efficiency benefits, featuring white reflective surfaces that can reduce cooling costs by 15-20% in hot climates. These thermoplastic membranes are heat-welded at seams, creating monolithic waterproof barriers that resist wind uplift, chemicals, and UV degradation. TPO systems typically provide a 20-25-year service life with proper maintenance.

PVC roofing membranes offer superior chemical resistance, making them ideal for restaurants, food processing facilities, and industrial properties that are exposed to grease or chemicals. These membranes resist many oils, greases, and chemicals that can degrade other roofing materials, while offering excellent fire resistance and energy efficiency. PVC systems provide exceptional durability in challenging environments.

EPDM roofing delivers outstanding weather resistance and flexibility, maintaining performance characteristics across extreme temperature ranges. Black EPDM absorbs heat, which can benefit heating costs in cold climates but may increase cooling loads in warmer regions. White EPDM formulations address energy efficiency concerns while maintaining the material’s proven durability. EPDM systems can last 25-30 years with proper maintenance.

Installation of single-ply membranes involves mechanically fastening, fully adhering, or ballasting membranes to create watertight seals. Mechanical attachment uses fasteners through insulation into the roof deck, while fully adhered systems use specialized adhesives for complete bonding. Ballasted systems place loose stone over membranes, providing wind resistance through weight rather than attachment.

Built-Up and Modified Bitumen Roofing

Built-up roofing (BUR) systems use alternating layers of bitumen and reinforcement fabric, creating robust multi-ply membranes topped with gravel or mineral cap sheets. These time-tested systems provide excellent redundancy—if one layer develops issues, underlying layers continue protecting the building while repairs are planned and executed.

The installation process involves applying hot asphalt or coal tar between reinforcing plies, building up waterproof membranes in multiple layers. Surface treatments typically include gravel embedment for UV protection and fire resistance, though smooth-surfaced systems with mineral cap sheets are also common. BUR systems excel in high-traffic areas and can withstand heavy equipment installation better than single-ply alternatives.

Modified bitumen systems combine traditional asphalt technology with modern polymer science, incorporating rubber or plastic modifiers that enhance flexibility and durability. SBS (styrene-butadiene-styrene) modified systems remain flexible at low temperatures, while APP (atactic polypropylene) modified systems provide enhanced high-temperature performance and UV resistance.

These systems can be installed using torch application, hot mopping, cold adhesives, or self-adhering methods, depending on specific product formulations and project requirements. Multi-ply configurations typically involve a base sheet adhered to the substrate, followed by one or more intermediate plies, and finished with a mineral-surfaced cap sheet.

Both BUR and modified bitumen systems typically provide service lives of 20-25 years, depending on climate conditions, maintenance quality, and installation workmanship. These systems cost $6-12 per square foot installed, reflecting their labor-intensive installation requirements and robust material specifications.

Metal Commercial Roofing

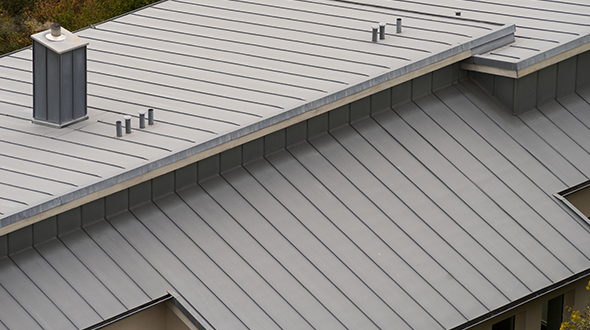

Metal roofing systems, particularly standing seam systems, offer exceptional longevity and performance for commercial applications. Standing seam systems use interlocking panels that run continuously from eave to ridge, with raised seams that accommodate thermal movement while concealing all fasteners beneath the seams.

Galvanized steel represents the most common metal roofing material, providing excellent strength-to-weight ratios and corrosion resistance when properly coated. Aluminum systems offer superior corrosion resistance and lighter weight, making them ideal for coastal environments or buildings with limited structural capacity. Both materials can support significant snow loads and equipment installations while maintaining structural integrity.

Cool metal roofing incorporates specialized reflective coatings that can reduce energy costs by up to 25% compared to traditional roofing materials. These coatings reflect solar radiation while maintaining high thermal emittance, keeping roof surfaces cooler and reducing air conditioning demands in commercial buildings.

Metal roofing systems provide 40-60 year lifespans with minimal maintenance requirements, making them attractive for long-term ownership scenarios despite higher initial costs. The systems excel in areas with severe weather conditions, providing excellent wind resistance, fire protection, and hail damage resistance.

Installation requires specialized expertise in metal fabrication, thermal movement accommodation, and weather sealing details. Proper installation ensures seams remain watertight throughout decades of thermal cycling while allowing for the substantial movement that occurs across large metal roof surfaces.

Commercial Roofing Installation and Maintenance

Commercial roofing projects involve complex coordination, specialized equipment, and strict adherence to safety protocols that distinguish them from residential installations. The scale, complexity, and performance requirements of commercial properties demand professional expertise and comprehensive planning throughout the project lifecycle.

Installation Process

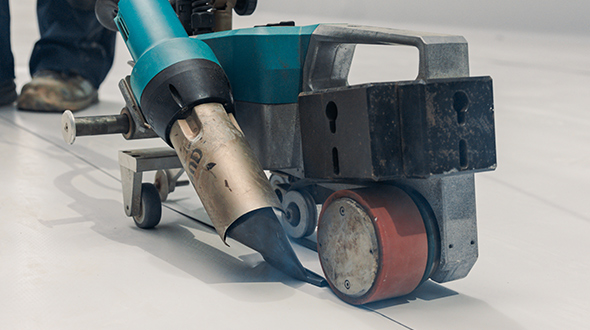

Commercial roof installations require specialized equipment, including cranes, hot air welders, material hoists, and safety systems designed for large-scale operations. Projects typically require 1-4 weeks, depending on building size, weather conditions, and system complexity, with detailed scheduling to minimize business disruption during installation.

The installation process begins with thorough substrate preparation, including structural assessments, removal of the existing roof when necessary, and deck repairs or modifications to meet current building codes. Insulation installation follows, with commercial buildings typically requiring R-25 to R-30 insulation values in most climate zones to meet energy efficiency requirements.

Installation must comply with stringent building codes, fire ratings, and wind uplift requirements specific to commercial structures. These requirements often exceed residential standards significantly, particularly regarding fire resistance classifications and wind uplift ratings that can exceed 90 pounds per square foot in high-wind zones.

Quality control throughout installation involves multiple inspections, testing of membrane seams, verification of fastener patterns, and documentation of all system components. Many commercial roofing projects require third-party inspections and testing to validate warranty compliance and building code conformance.

Weather coordination becomes critical for commercial installations due to project scale and exposure duration. Contractors must have contingency plans for precipitation protection, wind limitations for crane operations, and temperature requirements for membrane installations and adhesive applications.

Maintenance Requirements

Commercial roofs require professional inspections twice annually—typically in spring and fall—to identify potential issues before they develop into costly problems. These comprehensive inspections examine membrane surfaces, seams, flashings, drainage systems, and rooftop equipment interfaces for signs of deterioration or damage.

Regular maintenance includes cleaning debris from drains and gutters, inspecting membrane seams for separation, checking flashing around penetrations, and ensuring rooftop equipment hasn’t compromised membrane integrity through vibration or improper installation practices. Drainage system maintenance is particularly critical, as clogged drains can cause ponding water that accelerates membrane aging and creates structural concerns.

Preventive maintenance programs can extend roof service life by 50% while preventing approximately 85% of potential leaks when properly implemented. These programs include scheduled inspections, minor repairs, resealing of flashings, and proactive replacement of deteriorating components before failure occurs.

Emergency repairs must be addressed within 24-48 hours to prevent interior damage and business disruption. Commercial roofing contractors maintain emergency response capabilities, including temporary waterproofing systems that can protect interior spaces while permanent repairs are planned and executed.

Documentation of all maintenance activities, repairs, and inspections is essential for warranty compliance and asset management planning. Many commercial property owners maintain detailed roof condition databases that track performance trends, maintenance costs, and replacement timing for budgeting purposes.

Why Specialized Commercial Roofers Are Necessary

The complexity and specialized nature of commercial roofing systems demand contractors with specific training, experience, and capabilities that extend far beyond general construction or residential roofing expertise. These requirements reflect the critical nature of commercial roofing systems and their impact on business operations.

Commercial roofers require extensive training in fall protection systems, OSHA safety protocols, and safe working procedures around industrial equipment and occupied buildings. Working on commercial properties often involves complex safety coordination with ongoing business operations, requiring contractors who understand how to minimize disruption while maintaining strict safety standards.

Understanding building codes, fire ratings, and structural load requirements for commercial applications requires specialized knowledge that general contractors typically don’t possess. Commercial buildings must meet stringent performance standards for wind uplift resistance, fire classification, and energy efficiency that demand expertise in system design and installation methods.

Commercial roofing contractors carry substantially higher insurance coverage—typically $2-5 million in liability protection—due to project complexity, property values, and potential business interruption costs. This insurance reflects the higher risks associated with commercial work and provides property owners with protection against potential failures in installations or materials.

Experience with specialized techniques like membrane welding, modified bitumen installation, and complex flashing details is essential for quality workmanship. These skills require extensive training and practice that residential roofers typically don’t develop, as the techniques and materials are specific to commercial applications.

Commercial contractors also maintain relationships with specialized manufacturers and suppliers, ensuring access to commercial-grade materials and technical support throughout project execution. These relationships often include manufacturer training certifications that validate installer qualifications for warranty compliance.

Commercial Roofing Costs and Considerations

Commercial roofing represents a significant capital investment that requires careful financial planning and analysis of long-term costs versus benefits. Understanding the factors that influence costs helps property owners make informed decisions about system selection, contractor choice, and timing of replacement projects.

Commercial roofing costs range, depending on materials, building height, accessibility, and project complexity. This broad range reflects the substantial differences between basic single-ply installations and complex multi-story projects with extensive rooftop equipment and challenging access requirements.

TPO and EPDM roofing systems are popular choices for cost-conscious property owners who need reliable performance without premium pricing. These systems provide good value through proven durability, energy efficiency benefits, and relatively straightforward maintenance requirements.

Metal roofing systems have a higher material costs and specialized installation requirements. However, metal systems often provide superior long-term value through extended service lives, minimal maintenance requirements, and excellent energy efficiency, which can offset higher initial costs.

Several factors significantly impact project costs beyond basic material selection. Roof accessibility affects labor costs and equipment requirements, with high-rise buildings or complex roof configurations requiring specialized equipment and additional safety measures. Existing roof removal adds to project costs when complete tear-offs are necessary.

Insulation upgrades often accompany commercial roof replacements, particularly when buildings need to meet current energy codes. Insulation costs range depending on thickness and material selection, but energy savings often justify these investments through reduced utility costs over the roof’s service life.

Commercial roofing projects represent major investments ranging from $50,000 for small retail buildings to over $500,000 for large distribution centers or office complexes. This investment scale requires careful contractor selection, thorough contract review, and comprehensive warranty evaluation to protect the property owner’s interests.

Financing considerations often influence project timing and scope, with many property owners coordinating roof replacements with other building improvements to maximize efficiency and minimize business disruption. Lifecycle cost analysis becomes critical when comparing system options, as seemingly expensive systems may provide superior value over 20-30 year analysis periods.

Selecting a professional roofing contractor with commercial expertise, proper licensing, insurance coverage, and manufacturer certifications is essential to protecting this substantial investment. Quality installation directly impacts system performance, longevity, and warranty compliance, making contractor selection as important as material choice for long-term success.

When evaluating commercial roofing options for your property, consider working with experienced commercial roofing contractors who can provide detailed proposals, lifecycle cost analysis, and comprehensive warranty coverage. The complexity and investment level of commercial roofing systems make professional expertise essential for achieving optimal results that protect your business operations for decades to come.

(404) 220-9288